Thicker alumunium oxide layers can reduce ultraviolet-induced degradation in TOPCon solar cells

Thicker alumunium oxide layers can reduce ultraviolet-induced degradation in TOPCon solar cells

From:PV Magazine

UNSW researchers developed an experimentally validated model linking UV-induced degradation in TOPCon solar cells to hydrogen transport, charge trapping, and permanent structural changes in the passivation stack. They show that thicker aluminum oxide layers significantly improve UV resilience by limiting hydrogen migration, offering clear guidance for more robust TOPCon designs.

A solar cell fabricated at UNSW in Australia

Image: University of New South Wales

Share

Researchers from the University of New South Wales (UNSW) have investigated ultraviolet-induced degradation (UVID) in TOPCon solar cells and have found that thicker aluminum oxide (AlOx) layer can reduce this kind of

“Our new work provides a comprehensive, experimentally validated model for UV-degradation in TOPCon devices, linking electrical degradation directly to hydrogen dynamics and permanent structural changes in the passivation stack and was first presented in a plenary talk at the recent European PVSEC meeting in Bilbao, Spain,” the research's lead author, Bram Hoex, told pv magazine. “It builds directly on our earlier work on wavelength-dependent UVID and hydrogen dynamics, and we think it closes an important gap in understanding long-term TOPCon reliability.”

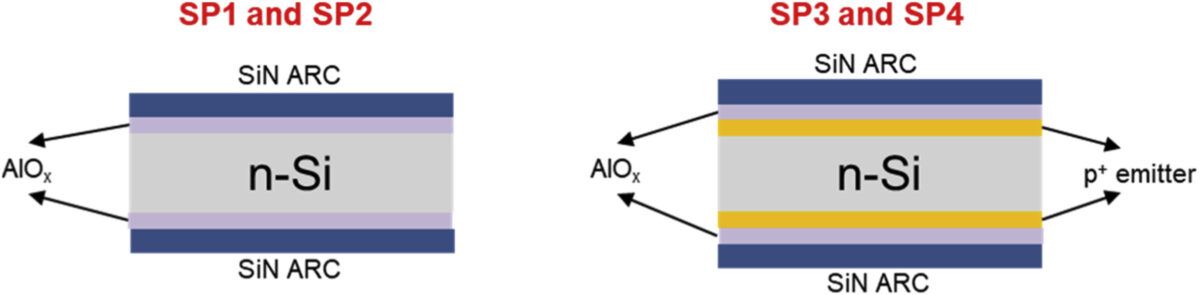

The tests were conducted on TOPCon cells based on n-type Czochralski (Cz) wafers fabricated on an industrial manufacturing line. The primary passivation stack consisted of an AlOx layer grown by atomic layer deposition (ALD) and a 75 nm silicon nitride (SiNx) capping layer deposited by plasma-enhanced chemical vapour deposition (PECVD).

The AlOx thickness was varied between 4 and 7 nm, reflecting the industrial TOPCon front-side passivation window. The 4 nm layer (SP1, SP3) represents a cost-efficient minimum, while the 7 nm layer (SP2, SP4) remains thin enough to avoid significant optical impact. “This comparison allows assessment of the trade-off between manufacturing throughput and UVID resilience,” the researchers explained.

Schematic of the symmetrical test structures used in the study

Image: UNSW, Solar Energy Materials and Solar Cells, CC BY 4.0

Corona-Oxide Characterisation of Semiconductors (COCOS) and Fourier-transform infrared spectroscopy (FTIR) were used to analyze changes in interface defect density (Dit) and negative fixed charge (Qf) under controlled UV exposure, dark storage, and thermal annealing conditions.

The measurements revealed a complex interaction between chemical degradation and a temporary, charge-trapping-induced enhancement in field-effect passivation, followed by a metastable decay during dark storage.

“We found that high-energy UV photons break silicon–hydrogen (Si–H) bonds in the SiNx capping layer, releasing mobile hydrogen that accumulates at the AlOx/Si interface and increases Dit, thereby degrading chemical passivation,” Hoex said. “At the same time, UV exposure temporarily improves field-effect passivation through charge trapping in AlOx, due to an increase in Qf.”

During subsequent dark storage, Qf de-traps, leading to further performance losses despite unchanged chemical damage. “Low-temperature dark annealing redistributes interfacial hydrogen into the silicon bulk, restoring chemical passivation through Dit recovery, but FTIR reveals a permanent structural rearrangement of the dielectric stack,” Hoex added. “Thicker 7 nm AlOx layers significantly improve UVID resilience by acting as a more effective barrier to hydrogen transport, rather than through differences in field-effect passivation.”

“This work establishes a unified physical model connecting UVID, hydrogen transport, charge trapping, and structural modification,” Hoex concluded. “It explains why some degradation is electrically reversible but structurally irreversible, and it provides clear design guidance for more UV-robust TOPCon passivation stacks as well as improved accelerated UV testing protocols.”

The research work was presented in “Charge trapping, hydrogen accumulation, and structural rearrangement: A complete model for ultraviolet-induced degradation in TOPCon devices,” published in Solar Energy Materials and Solar Cells.

In June, researchers from the University of Oxford in the United Kingdom and China’s metallisation paste specialist Changzhou Fusion New Materials identified a new failure mode in LECO-based TOPCon solar modules.

Other research by UNSW showed the impact of soldering flux on TOPCon solar cell performance, degradation mechanisms of industrial TOPCon solar modules encapsulated with ethylene vinyl acetate (EVA) under accelerated damp-heat conditions, as well as the vulnerability of TOPCon solar cells to contact corrosion and three types of TOPCon solar module failures that were never detected in PERC panels.

Furthermore, UNSW scientists investigated sodium-induced degradation of TOPCon solar cells under damp-heat exposure, the role of ‘hidden contaminants’ in the degradation of both TOPCon and heterojunction devices, and the impact of electron irradiation on PERC, TOPCon solar cell performance.