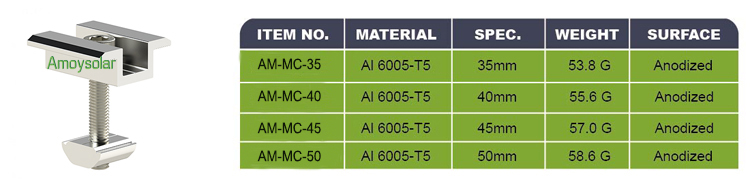

Aluminum Mid- Clamp 35-50mm for solar mounting

Brand Amoy

Product origin China

Delivery time 7 days

Whether you need framed panels for photovoltaic mounting fixtures or mounting fixtures for frameless panels, we can provide them all. Solar intermediate clips and end clips are always perfectly suited to different kinds of solar modules and photovoltaic mounting structures.

Amoy solar panel aluminum middle clip is made of extruded anodized aluminum material, which has good anti-rust and anti-corrosion properties, suitable for 35mm-50mm framed solar panels, and is exquisitely designed to make the connection between the panels firm.

Aluminum mid clamp

Whether you need framed panels for photovoltaic mounting fixtures or mounting fixtures for frameless panels, we can provide them all. Solar intermediate clips and end clips are always perfectly suited to different kinds of solar modules and photovoltaic mounting structures.

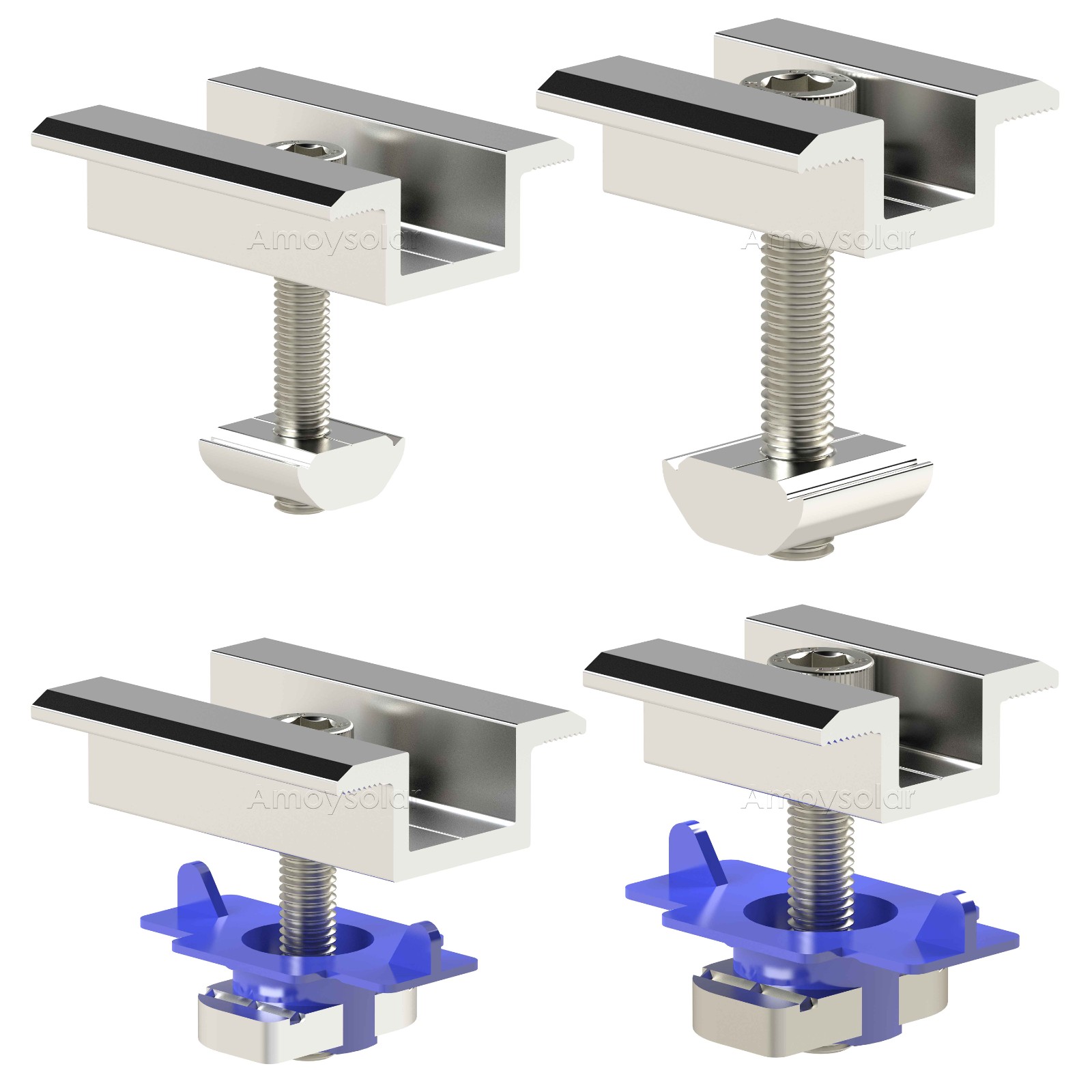

Amoy solar panel aluminum middle clip is made of extruded anodized aluminum material, which has good anti-rust and anti-corrosion properties, suitable for 35mm-50mm framed solar panels, and is exquisitely designed to make the connection between the panels firm. The aluminum middle clip of the solar bracket is used to clamp the solar panel between two solar modules by fixing it with rails, which firmly clamps the solar panel against wind and any other shocks. Usually anodized on surface finish, milled finish is also available upon customer request. We have silver and black for you to choose or customize to meet your needs. Our factory offers different series of middle clips, including 30/35/40/45/50mm etc. to fit solar panels. The aluminum middle clamp for solar panel is equipped with socket head cap screws, flat washers, spring washers and sliding nuts. It can also be fitted with a grounding clip to attach to the mounting rail for grounding recommendations.

We take the quality of our middle clips seriously and offer a guarantee for our other products.

Component list

Product Description

| product name | Aluminum mid clamp |

| Brand | Amoy |

| Assemble Stie | Solar Mounting Rail |

| Tilt Angle | 5°~ 60° |

| Max Wind Speed | 45m/s |

| Max Snow Load | 1.4KN/m² |

| Material | Aluminum 6005-T5 & SUS 304 |

| Surface Treatment | Anodized |

| Certification | ASNZS1170/intertek/SGS/Gamcorp/MCS/Intertek/SPAD |

| Warranty | 10 Years |

| Duration | More than 20 year |

Features

1、High class anodized aluminum

2、Easy to install

3、Pre-assembled

4、 Flexible post spacing withstands different wind & snow loads

5、 Available in Mill Finish, Clear Anodized, or Black Anodized Hardware

FAQ

Q:Are you a factory or trading company?

A: Xiamen Amoy Solar Technology is a high-tech enterprise that seamlessly integrates R&D, precision manufacturing, and global sales of photovoltaic (PV) mounting and balance-of-system products.

Q: Where is your factory located?

A: Our factory is located in Xiamen city, Fujian province,China.

Q: How can I get some samples?

A: We are honored to offer you samples according to your inquiry.

Q: How does you factory do regarding quality control?

A: "Quality is priority" , as an ISO 9001 certified manufacturer, we are capable of strict quality and management control from the very beginning to the end.

Q:What necessary info for us to design and quote?

1. What is your pv panels dimension? Length x_____mm Width x____mm Thickness

2.How many panel are you going to mount? _______Nos.

3.Do you have any special requirement on ground/flat roof clearance?

4.May I know the tilt angle you need?________degree

5.What is your planned pv assmebly block? ________Nos. in a row,___rows

6.How is weather there, such as wind speed and snow load?___m/s anit-wind speed and____KN/m2 snow load.

Q:What can you get by choosing Amoy?

A: Premium Solar Mounting Solutions – Engineered for Performance, Built for Life

Source Factory Quality Control

Every component is manufactured and inspected in our own ISO-certified facility, ensuring traceability, consistency, and zero-compromise quality from raw material to finished product.Private Design Scheme

Our in-house R&D team delivers exclusive, patent-ready solutions tailored to your roof type, terrain, and local wind-snow loads—no one-size-fits-all brackets.Factory Pre-assembled, Easy to Install

Up to 80 % of parts are pre-assembled and labeled in our plant. A two-person crew can finish a 5 kW array in under 2 hours—cutting labor costs by up to 40 %.10-Year Warranty, 25-Year Service Life

Anodized aluminum 6005-T5 rails, SUS 304 fasteners, and rigorous salt-spray & UV testing deliver proven durability backed by an industry-leading warranty.Support Customer Customization & Free Sample Service

Need a custom color, logo, or packaging? MOQ starts at 1 set for samples and 50 sets for OEM batches. Free samples ship within 7 days so you can validate before you scale

Company

ABOUT US :

Xiamen Amoy Solar Technology is a high-tech enterprise that seamlessly integrates R&D, precision manufacturing, and global sales of photovoltaic (PV) mounting and balance-of-system products. Leveraging our own aluminum-extrusion mills and CNC-machining plants, we maintain a fully traceable, vertically integrated supply chain that guarantees material consistency, on-time delivery, and strict cost control.

Our in-house structural engineers and certified designers apply rigorous wind-load, snow-load, and seismic calculations to every project—whether a multi-megawatt ground installation or a distributed rooftop array—ensuring code compliance and 25-year reliability. We currently serve leading module manufacturers, EPC contractors, and independent power producers across five continents.

Mission

To deliver stable, reliable, and cost-effective PV mounting solutions that maximize energy yield and minimize LCOE for our customers worldwide.

Contact us today for quotations, technical drawings, or complimentary samples.

We primarily use high-strength aluminum alloys, specifically international standards 6005-T5. This grade undergo strict heat treatment processes and offer the following core advantages: High Strength & Light Weight: They provide exceptional structural strength while being significantly lighter than steel, reducing shipping costs and simplifying installation, thereby lowering the overall load on...more